Wondering if your cozy wood burning stove might be silently releasing dangerous carbon monoxide into your home? You’re not alone. This invisible, odorless gas poses serious health risks, and understanding its relationship with your wood stove is crucial for your family’s safety.

We’ve researched extensively to bring you clear, definitive answers about carbon monoxide production in wood burning stoves. While these traditional heating methods add warmth and charm to any space, they do produce carbon monoxide during the combustion process—but that doesn’t mean they’re unsafe when properly installed and maintained.

Understanding Wood Burning Stoves and Carbon Monoxide

Wood burning stoves generate heat through the combustion process, which naturally produces carbon monoxide as a byproduct. The relationship between these stoves and carbon monoxide production stems from how wood burns and the chemical reactions that occur during combustion. Carbon monoxide forms when there’s insufficient oxygen for complete combustion, resulting in partial oxidation of carbon in the wood.

Modern wood stoves are designed with features that minimize carbon monoxide production. EPA-certified models incorporate secondary combustion chambers and catalytic converters that help burn gases more completely. These technological improvements reduce carbon monoxide emissions by up to 90% compared to older stove models manufactured before 1990.

The amount of carbon monoxide released depends on several factors including the stove’s design, fuel type, and how the fire is managed. Seasoned hardwoods like oak and maple burn more efficiently and produce less carbon monoxide than wet or green wood. Operating your stove with adequate airflow also ensures more complete combustion, significantly reducing harmful emissions.

Wood burning stoves don’t present a carbon monoxide danger when properly installed, maintained, and operated according to manufacturer guidelines. Regular chimney cleaning, proper ventilation, and monitoring with carbon monoxide detectors create a safe environment for enjoying the benefits of wood heat. Professional installation ensures appropriate clearances and venting configurations that allow gases to safely exit your home.

The Science of Wood Combustion

Wood burning stoves produce carbon monoxide (CO) as a byproduct of incomplete combustion. This colorless, odorless gas forms when wood doesn’t burn completely due to insufficient oxygen or poor airflow conditions within the stove.

Complete vs. Incomplete Combustion

Complete combustion occurs when wood burns efficiently with adequate oxygen supply, producing primarily carbon dioxide and water vapor. The process requires optimal fuel-to-air ratios, which modern certified stoves are designed to achieve through improved airflow systems. EPA-certified models feature technology that maximizes burning efficiency and minimizes harmful emissions.

Incomplete combustion happens when oxygen levels are restricted during the burning process. Under these conditions, carbon monoxide production increases dramatically as the wood fuel can’t fully oxidize. Factors like wet wood, clogged air vents, or improper stove operation contribute to this inefficient burning process, resulting in higher CO levels that pose serious health risks.

Factors Affecting Carbon Monoxide Production

Ventilation plays a critical role in determining CO levels from wood stoves. Insufficient airflow during operation significantly raises carbon monoxide production, making properly installed flues, chimneys, and unobstructed air vents essential safety components. Regular inspection ensures these pathways remain clear and functional.

Stove efficiency varies dramatically between models, with non-certified stoves emitting substantially higher CO levels—equivalent to driving 20 miles for every 4 hours of operation. Certified models incorporate design features that enhance combustion efficiency and reduce harmful emissions through secondary burn chambers and improved airflow management.

Fuel quality directly impacts carbon monoxide production in wood burning systems. Dry, seasoned wood with moisture content below 20% burns cleaner and more efficiently, while damp or resinous wood promotes incomplete combustion and increases CO output. Testing wood with a moisture meter helps ensure optimal burning conditions.

Maintenance issues like blocked chimneys, creosote buildup, or damaged door seals can trap carbon monoxide indoors instead of allowing it to vent properly. Annual professional inspections are recommended to identify and address these potential hazards, as CO poisoning causes approximately 50 accidental deaths annually in the UK alone.

Health Risks of Carbon Monoxide Exposure

Carbon monoxide (CO) poses serious health threats due to its ability to bind with hemoglobin in the blood. This binding process reduces oxygen transportation throughout the body, leading to tissue damage and potentially fatal consequences when exposure is prolonged or at high concentrations.

Symptoms of Carbon Monoxide Poisoning

Early carbon monoxide poisoning symptoms often mimic common illnesses, making detection challenging without proper monitoring equipment. Headaches typically develop first, followed by dizziness, nausea, and unusual fatigue during initial exposure. More severe cases progress to confusion, impaired coordination, and eventually loss of consciousness if the exposure continues. These flu-like symptoms frequently result in delayed diagnosis, putting victims at greater risk as they remain in the contaminated environment. Physical indicators like bright red skin coloration may appear in some cases, though many victims show no visible external signs of poisoning.

Vulnerable Populations

Certain groups face heightened risks from carbon monoxide exposure due to physiological factors affecting how their bodies process the gas. Infants and young children experience more severe effects due to their higher metabolic rates and developing nervous systems. Elderly individuals often show symptoms at lower exposure levels because of reduced respiratory efficiency and preexisting health conditions. Pregnant women deserve special protection since carbon monoxide crosses the placental barrier and binds more readily to fetal hemoglobin, potentially causing developmental issues. People with existing cardiovascular or respiratory conditions experience amplified symptoms as their bodies already struggle with oxygen utilization. The U.S. reports thousands of CO-related emergency room visits annually, with similar risk patterns observed globally across these vulnerable demographics.

Measuring Carbon Monoxide From Wood Stoves

Accurate measurement of carbon monoxide (CO) emitted by wood burning stoves is essential for maintaining indoor air quality and ensuring safety. Professional-grade carbon monoxide detectors provide precise readings that help homeowners understand their exposure levels and take appropriate safety measures.

Safe Carbon Monoxide Levels

Carbon monoxide concentration is measured in parts per million (ppm), with different thresholds indicating varying levels of safety. Exposure levels between 0-100 ppm are generally considered safe for short-term exposure, though prolonged exposure even at lower levels can affect sensitive individuals. Concentrations between 100-200 ppm often trigger mild health symptoms like headaches, while readings above 400 ppm can cause more serious effects including confusion and impaired judgment. Many carbon monoxide detectors will sound an alarm when CO levels reach approximately 70 ppm, providing an early warning system before concentrations become dangerous. Health organizations recommend keeping indoor CO levels as low as possible, ideally below 50 ppm for extended periods, to minimize long-term health risks from wood stove emissions.

Digital CO monitors offer the advantage of displaying real-time readings, allowing homeowners to track levels throughout the day and observe how different activities—such as adding wood or adjusting air vents—affect carbon monoxide production. Professional chimney sweeps and heating technicians use specialized equipment during annual inspections to measure CO levels at various points in the home and identify potential leakage from the stove system. Regular monitoring becomes particularly important during winter months when homes are more tightly sealed and wood stoves operate for longer periods.

Prevention Measures for Wood Stove Owners

Wood stove owners must carry out several critical safety measures to minimize carbon monoxide exposure risks. These preventative steps significantly reduce the dangers associated with CO production during wood burning.

Proper Installation Requirements

Professional installation of wood burning stoves in well-ventilated areas minimizes carbon monoxide accumulation. Certified technicians ensure proper clearances from combustible materials and correct connection to compliant flue and chimney systems that safely expel all combustion byproducts. The installation location plays a crucial role in CO safety, as improper placement can restrict airflow and trap dangerous gases indoors. Avoiding space heater-like misuse is essential since improper operation dramatically increases carbon monoxide emissions – non-certified stoves can emit CO levels equivalent to driving a car for 20 miles during just four hours of use. EPA-certified models incorporate advanced combustion technology that reduces these emissions substantially while maintaining efficient heating.

Regular Maintenance and Inspection

Annual professional inspections assess combustion efficiency and venting integrity, identifying potential CO hazards before they become dangerous. Chimney sweeping prevents blockages from creosote buildup or debris that could hinder proper exhaust flow and force carbon monoxide back into living spaces. Regular appliance condition checks help identify leaks, cracks, or faulty components that might compromise the sealed combustion system. Between professional visits, homeowners should install certified CO alarms on every level of their home, particularly near sleeping areas, to detect dangerous carbon monoxide levels before they cause symptoms. Burning only dry, seasoned wood labeled specifically for indoor use reduces incomplete combustion risks that lead to higher CO production. Maintaining unobstructed air vents and ensuring adequate fresh air intake creates the optimal environment for complete combustion, minimizing carbon monoxide generation while maximizing heat output.

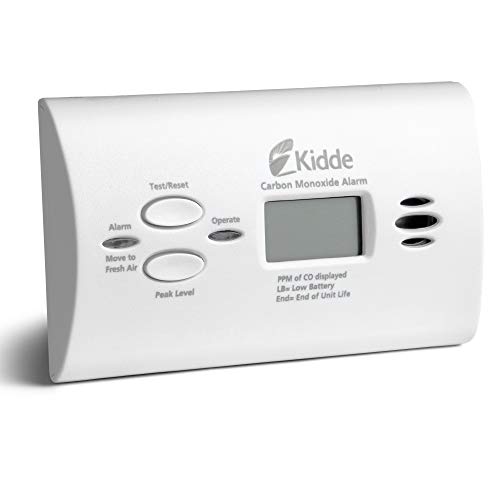

Carbon Monoxide Detectors: Your Essential Safety Net

Carbon monoxide detectors provide a critical line of defense against this invisible threat, acting as your early warning system when CO levels become dangerous. Human senses cannot detect carbon monoxide, making these devices non-negotiable for all wood stove owners. Strategic placement of CO detectors near sleeping areas ensures they’ll alert you to rising levels before symptoms develop.

Monthly testing of your carbon monoxide detectors helps confirm they’re functioning properly. Annual battery replacement, even in hardwired models, prevents power failures from compromising your safety. Most detector units last between 5-7 years before requiring replacement, with manufacturing dates typically marked on the device.

Modern CO detectors sound alarms at approximately 70 ppm, giving households ample time to ventilate and investigate the source. Digital models offer real-time monitoring capabilities, allowing you to track CO levels throughout your home. Multiple detectors installed on each floor provide comprehensive coverage, especially important for homes with wood stoves on different levels.

Remember that CO detectors complement—not replace—proper stove maintenance and ventilation practices. Four hours of burning an uncertified wood stove produces carbon monoxide equivalent to driving a car for 20 miles. Combining certified stoves with functional detectors, proper venting, and routine maintenance creates a robust safety system that significantly reduces your exposure risk.

Modern Wood Stove Technologies Reducing Emissions

Modern wood stoves incorporate innovative technologies that significantly reduce carbon monoxide emissions compared to older models. EPA-certified wood heaters now cut CO emissions by 62% (46,100 tons annually) from pre-regulation levels, making them substantially cleaner and safer for indoor use.

Secondary Combustion Systems

Secondary combustion systems represent a major advancement in wood stove technology. These systems introduce additional air to the combustion chamber, allowing for the reburning of gases that would otherwise escape as pollutants. By creating a secondary burn zone, these stoves achieve more complete combustion of wood gases, reducing carbon monoxide and particulate matter emissions substantially. The additional oxygen helps convert carbon monoxide into carbon dioxide, resulting in cleaner emissions and improved heating efficiency.

Catalytic Converters

Catalytic converters transform how wood stoves process exhaust gases. Located in the stove’s exhaust path, these honeycomb-structured devices are coated with precious metals that lower the ignition temperature needed for complete combustion. Smoke and gases that would normally exit the chimney instead pass through the catalytic element where they burn at temperatures as low as 500°F—much lower than the 1,100°F required in non-catalytic systems. This process dramatically reduces carbon monoxide output while extracting additional heat from the fuel, improving overall efficiency by 10-15% compared to non-catalytic models.

Automated Airflow Controls

Automated airflow control systems optimize the oxygen supply throughout the burning process. These sophisticated controls monitor combustion conditions and adjust air intake accordingly, preventing the oxygen-starved environment that leads to incomplete combustion—a major source of carbon monoxide. Some advanced models feature:

- Thermostatically controlled dampers that respond to temperature changes

- Microprocessor-based systems that maintain optimal combustion parameters

- Precision air delivery systems that target different burning zones within the stove

Through proper operation of these modern technologies, homeowners can achieve 50-80% reduction in emissions compared to older stove operation methods. The combination of improved design, better airflow management, and enhanced combustion efficiency makes today’s wood stoves dramatically safer about carbon monoxide production than their predecessors.

Conclusion

Wood burning stoves do produce carbon monoxide but with proper precautions they don’t have to pose a health risk. Modern EPA-certified stoves with advanced combustion technology have dramatically reduced emissions by up to 90% compared to older models.

Safety relies on professional installation proper ventilation regular maintenance and vigilant monitoring. Installing carbon monoxide detectors near sleeping areas provides crucial early warnings of dangerous CO levels that our senses can’t detect.

By burning only seasoned hardwood maintaining clean chimneys and following manufacturer guidelines we can enjoy the warmth and ambiance of wood stoves while keeping our families safe. The combination of improved technology proper practices and monitoring systems makes today’s wood burning experience both safer and more environmentally responsible.

Frequently Asked Questions

Can wood burning stoves produce carbon monoxide?

Yes, wood burning stoves naturally produce carbon monoxide during the combustion process. This occurs especially during incomplete combustion when there’s insufficient oxygen available. However, modern EPA-certified stoves are designed to minimize CO emissions through improved airflow systems and secondary combustion chambers, reducing emissions by up to 90% compared to older models.

What are safe carbon monoxide levels in a home with a wood stove?

Concentrations between 0-50 ppm are generally considered safe for extended periods. Most carbon monoxide detectors sound alarms at around 70 ppm. Levels above 100 ppm may cause mild symptoms with short-term exposure, while concentrations above 400 ppm can lead to serious health effects. Health organizations recommend keeping indoor CO levels below 50 ppm to minimize long-term health risks.

What are the symptoms of carbon monoxide poisoning?

Early symptoms include headaches, dizziness, nausea, and fatigue – often mistaken for flu-like illness. More severe exposure can cause confusion, impaired coordination, and loss of consciousness. CO poisoning is particularly dangerous because symptoms can develop gradually and may not be recognized until significant exposure has occurred. If multiple household members experience similar symptoms simultaneously, suspect CO poisoning.

How can I prevent carbon monoxide exposure from my wood stove?

Ensure professional installation with proper ventilation and clearance from combustible materials. Conduct annual inspections and chimney sweeping to prevent blockages. Burn only dry, seasoned hardwood. Install CO detectors on every level of your home, particularly near sleeping areas. Keep air vents unobstructed and maintain your stove according to manufacturer guidelines. Never sleep in the same room as an operating wood stove.

Where should carbon monoxide detectors be placed in homes with wood stoves?

Install CO detectors on every level of your home, with priority locations being outside sleeping areas and in the same room as the wood stove (but not directly above or beside it). Position detectors at least 15 feet from the stove to prevent false alarms. For optimal protection, place additional detectors in hallways leading to bedrooms and in rooms where people spend significant time.

How often should I have my wood stove inspected?

Have your wood stove and chimney professionally inspected and cleaned at least once annually, ideally before the heating season begins. More frequent inspections may be necessary for heavily used stoves or when burning softer woods that produce more creosote. Regular maintenance prevents dangerous buildup that can restrict airflow and increase carbon monoxide production.

Are modern wood stoves safer than older models regarding CO emissions?

Yes, modern EPA-certified wood stoves are significantly safer, reducing CO emissions by up to 62% compared to pre-regulation models. They feature advanced technologies like secondary combustion chambers, catalytic converters, and automated airflow controls that enable more complete combustion. These improvements not only minimize carbon monoxide production but also increase heating efficiency by 50-80%.

Who is most vulnerable to carbon monoxide poisoning?

Infants, young children, elderly individuals, pregnant women, and people with pre-existing cardiovascular or respiratory conditions face heightened risks from carbon monoxide exposure. Their bodies may have reduced capacity to process CO or increased sensitivity to its effects. These vulnerable populations should take extra precautions when living in homes with wood burning stoves.

How can I tell if my wood stove is producing too much carbon monoxide?

Without a carbon monoxide detector, you cannot reliably detect excessive CO levels since the gas is colorless and odorless. Warning signs include yellow or orange flames instead of blue, sooty stains around the stove, excessive smoke, or difficulty keeping the fire burning. If you experience unexplained headaches or dizziness while the stove is operating, ventilate immediately and have the stove inspected.

What should I do if my carbon monoxide detector alarms?

Immediately open windows and doors to ventilate your home. Turn off the wood stove if possible and evacuate everyone, including pets. Call emergency services from outside the home. Do not reenter until emergency responders declare it safe. Seek medical attention if anyone shows symptoms of CO poisoning, even if symptoms seem mild.