If you’ve ever tackled a woodworking project, you know the importance of a flawless finish. Wood filler is your go-to solution for hiding imperfections, but have you ever wondered if it needs a hardener to truly deliver long-lasting results? This question can make or break the durability and appearance of your work.

Choosing the right approach can save you from cracks, shrinkage, or a filler that just won’t hold up over time. Whether you’re repairing furniture, patching floors, or filling gaps, understanding how hardener affects wood filler is key to achieving professional-level results. Don’t leave your project’s success to chance—let’s uncover what your wood filler really needs.

What Is Wood Filler?

Wood filler is a malleable substance designed for filling gaps, holes, and imperfections in wood surfaces. It plays a crucial role in achieving smooth and flawless finishes.

Purpose And Uses Of Wood Filler

Restoring damaged wood is one of its main uses. You can apply wood filler to repair holes, dents, or cracks in doors, furniture, or hardwood floors. Smoothing out irregularities allows for a seamless surface before painting or staining.

Improving structural integrity is another benefit. Small voids or weak areas in wood can weaken projects, but fillers ensure stability for a long-lasting result. In woodworking, professionals use it to blend joints and hide seams to enhance visual appeal.

Types Of Wood Fillers Available

Solvent-based fillers are durable and ideal for outdoor use. These fillers resist water and extreme weather conditions, making them suitable for decks or fences. Cleanup requires solvents like mineral spirits.

Water-based fillers dry faster and are more eco-friendly. They’re easier to clean with just soap and water. Typically used for interior projects, these fillers blend seamlessly with wood stains and paints.

Epoxy-based fillers are versatile and provide exceptional adhesion. They’re perfect for repairing severe damage or rotting wood. Mixing a hardener with epoxy fillers ensures a stronger bond and enhances performance.

Latex-based fillers are flexible and resist cracking. You can use them in projects requiring frequent movement, such as window frames or wooden trim. These fillers are also stainable and compatible with paints.

Role Of Hardeners In Wood Filler

Hardeners enhance the functionality of certain wood fillers by improving their strength and durability. Their inclusion influences the filler’s ability to handle stress, maintain form, and resist damage over time.

How Hardeners Affect Wood Filler Performance

Hardeners chemically react with exact wood fillers to stabilize their structure. This reaction accelerates curing time, allowing you to complete projects faster. The cured material becomes denser, resisting cracks and shrinkage even in heavy-use areas.

Some fillers without hardeners struggle with large gaps or high-traffic zones due to reduced durability. Adding a hardener boosts the filler’s adhesion to wood fibers, increasing its effectiveness for repairs requiring structural support, such as filling deep gouges or fixing outdoor wooden furniture.

Their contribution also includes improved water resistance when paired with fillers like epoxy-based types. This property ensures the material withstands environmental conditions in exposed settings. Hardened wood fillers maintain a smooth finish and reduce the need for frequent touch-ups.

Examples Of Wood Fillers With Hardeners

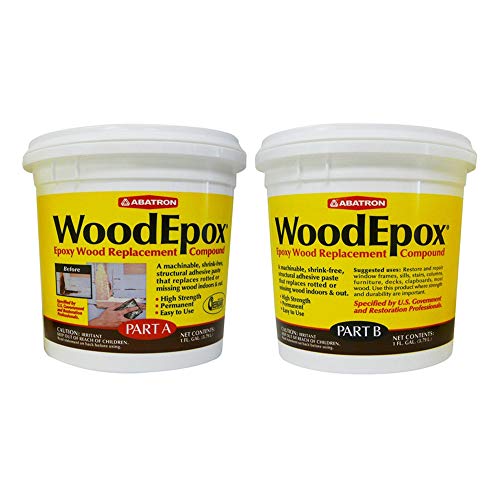

Epoxy fillers often include hardeners to deliver exceptional bonding and durability. Products like Abatron WoodEpox exemplify this, featuring a two-component system combining the base filler with a hardener.

Automotive-grade fillers, including Bondo, also rely on hardeners for structural repairs. These are ideal for larger wood restoration projects where strength is critical. Polyester-based fillers frequently come with hardeners that activate curing, enabling use in both woodworking and construction applications.

Selecting a system with a hardener depends on the project. For example, outdoor furniture thrives on weather-resistant epoxy fillers, while indoor repairs often favor solvent-based alternatives with added hardeners for stability.

Does Wood Filler Always Need Hardener?

Some wood fillers rely on hardeners for optimal performance, but not all require them. The necessity depends on the type of filler and the exact application.

Situations Where Hardener Is Necessary

Certain woodworking tasks demand hardeners to ensure lasting results. Deep repairs, like filling large holes or gouges, benefit from added structural stability when hardener is used. Outdoor projects, such as repairing external furniture or decks, often require hardener-enhanced fillers to withstand weather exposure. High-traffic areas on wooden surfaces, like floors, need the extra resistance to cracks and wear provided by hardener. Some solvent-based and epoxy fillers include hardeners to reduce curing time and enhance durability.

When Hardener Might Not Be Required

In other cases, wood fillers perform well without hardeners. Small repairs, like patching minor nail holes or surface scratches, don’t always need the added strength. Sanding and finishing tasks typically use water-based fillers, which maintain a smooth finish without hardener. Eco-conscious projects or situations requiring low-odor materials often favor water-based or latex fillers, neither of which generally involve hardeners. Temporary fixes or projects that don’t face important stress may also forgo hardener without compromising results.

Pros And Cons Of Using Hardener With Wood Filler

Using a hardener with wood filler delivers exact advantages but also presents some potential drawbacks. Evaluate these factors to align with your project’s needs.

Advantages Of Adding Hardener

Hardeners improve the structural integrity of wood filler. When used, they create a durable bond that prevents cracks and shrinkage. For high-traffic areas like floors or outdoor surfaces, adding a hardener increases resistance to wear and environmental elements. This feature is essential for outdoor furniture or areas exposed to moisture.

Curing time reduces significantly with the right hardener. Faster curing is ideal when deadlines require quicker project completion. Hardeners also enhance adhesion to wood fibers, which ensures long-lasting repairs for deep gouges or extensive filling.

Possible Drawbacks Or Limitations

Some fillers may become overly rigid with hardener. Excess rigidity can pose challenges, especially in flexible wood surfaces. Cost increases since hardeners are sold separately in some cases. You might also find use more complex, as precise mixing is required to achieve desired properties.

Limited work time occurs because hardeners accelerate filler curing. If not planned efficiently, faster curing might reduce application precision. In small repairs, hardeners might be unnecessary, as they could result in waste or unwanted material hardness.

Tips For Choosing The Right Wood Filler

Selecting a suitable wood filler ensures durability, appearance, and performance for your woodworking projects. Make informed decisions by evaluating key aspects that align with your project needs.

Assessing Project Requirements

Determine the scope of your repair to guide filler selection effectively. For structural repairs like deep gouges or heavy-duty tasks, use epoxy fillers that include hardeners for greater strength. Smaller imperfections, such as nail holes or minor cracks, require lightweight, easy-to-sand fillers. Check if the filler allows staining or painting to maintain consistency with the wood surface. For furniture refinishing, choose a filler that can mimic wood’s texture and color after finishing.

Considering Environmental Factors

Evaluate the environment where the wood piece will be used before selecting a filler. Outdoor applications call for solvent-based or epoxy fillers due to their weather resistance and durability. For indoor work, especially in areas with minimal moisture, water-based or latex fillers provide an eco-friendly, low-odor solution. Consider temperature and humidity as these affect the filler’s curing time and performance. Use fillers with added hardeners in high-traffic settings for enhanced durability against wear and tear.

Conclusion

Deciding whether wood filler needs a hardener depends on the specifics of your project. Understanding the type of filler and the demands of your application ensures you achieve durable and visually appealing results. By carefully evaluating factors like repair depth, environmental conditions, and project scope, you can select the most effective solution.

Whether you’re restoring furniture, patching floors, or tackling outdoor repairs, the right combination of wood filler and hardener can make all the difference. Prioritize your project’s unique requirements to create professional-quality finishes that stand the test of time.